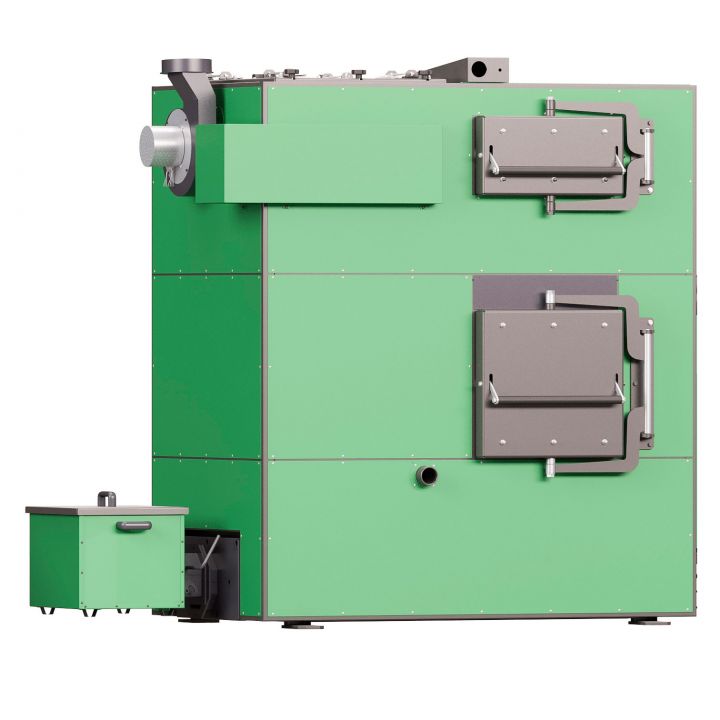

Smok Premium Set

Power: 120/240 kW

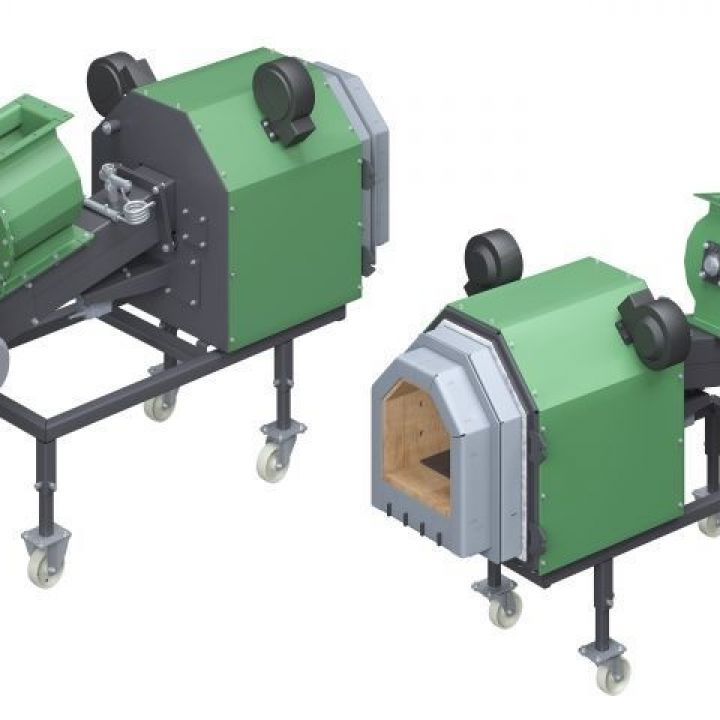

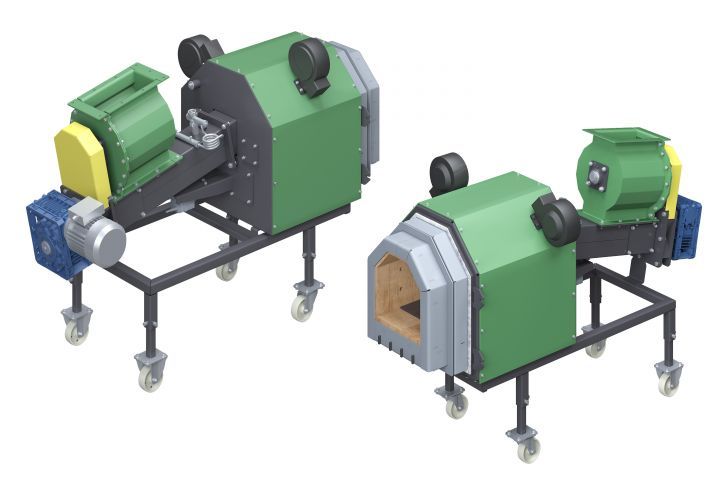

Automatic Biomass Burning Set - SMOK with a cast iron head is a modern device consisting of an heat exchanger, a fuel burning head, feeding system, fuel tank or a spring feeder.

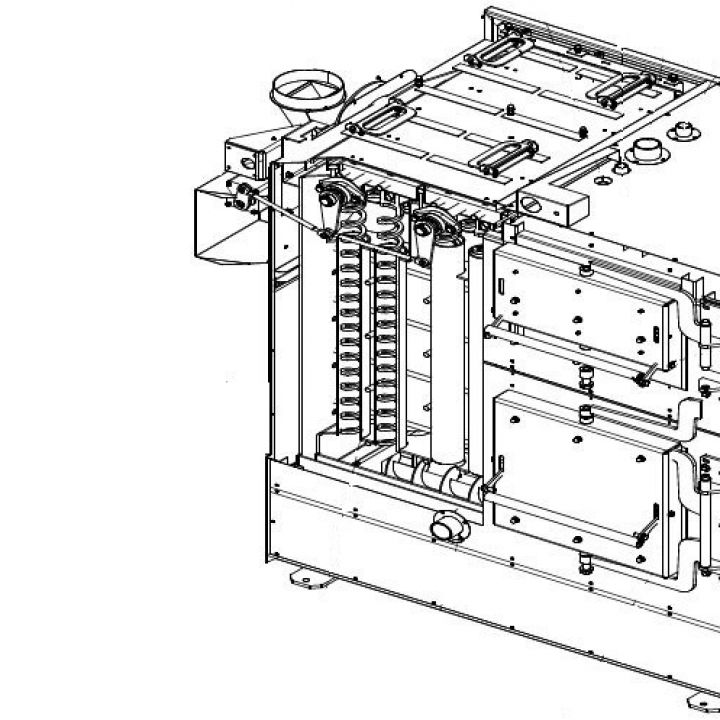

The heat exchanger is equipped with an innovative self-cleaning system. The burner has a mechanical system for cleaning the furnace and ash removal system. Two fans: supply and exhaust, provide a uniform air distribution system resulting in an excellent level of combustion efficiency and emission of pollution, the highest class 3 according to EN 303-5. Control of the combustion process is controlled by the latest PLUM control systems.

A large range of fuel tanks (4m3, 6m3, 8m3, 10m3, 27m3) or the use of a spring feeder the device to fit properly to any housing conditions.

All these elements form a universal device "SMOK" with a high level of automation and a minimal degree of involvement in use and operation.

It is most often assembled in production plants where fuel is created as a by-product, but also used for heating halls with large areas, offices, schools, hotels, sacral buildings and large single-family houses.

| Parameter | units | AZSB60 RA | AZSB120 RA | AZSB180 RA | AZSB240 RA |

| Nominal power | kW | 60 | 120 | 180 | 240 |

| Power range | kW | 18-60 | 36-120 | 54-180 | 72-240 |

| efficiency in nominal power | 90 | 90 | 90 | 90 | |

| Exhaust temp. In nominal power | oC | 140 | 150 | 160 | 160 |

| Water capacity of boiler | l | 205 | 480 | 720 | 910 |

| Max. Power cosumption | W | 2150 | 2300 | 2400 | 2800 |

| Igniter power consumption | W | 2000 | 2000 | 2000 | 2000 |

| Required chimney draft | Pa | 36 | 41 | 45 | 47 |

| Chimney dimensions | cm x cm | 22x22 | 30x30 | 35x35 | 40x40 |

| Ø mm | 220 | 300 | 350 | 400 | |

| Min. Chimney height | m | 8-10 | 8-10 | 8-10 | 10-12 |

| Eshaust diameter | Ø mm | 160 | 160 | 160 | 180 |

| Diameter of supply and return connectors | DN40 (G6/4 elbows) | DN50 (G2 elbows ) nakrętne) | DN50 (G2 elbows) | DN80 (flange) | |

| Max. Working pressure | bar | 1,5 | 1,5 | 1,5 | 1,5 |

Equipment

- automatic cleaning system for convection surfaces of heat-exchanger

- automatic ash removal system in front and back part of heat-exchanger

- exhaust fan

- automatic burner's cleaning system - moving grate

- innovative ash removal system from under-grate space in the burner

- multi-point air distribution system in the burner

- lighter/igniter (automatic fully safe start&stop system)

- effective fire protection systems: BVTS valve, feeder housing temperature sensor, additional cell feeder

Cast-iron burners

Designed for combustion of shredded renewable fuels (P45 wood chips, some types of sawdust, bark, peat, pellets, briquettes with bulk density up to 450 kg / m3) with relative humidity up to 25%

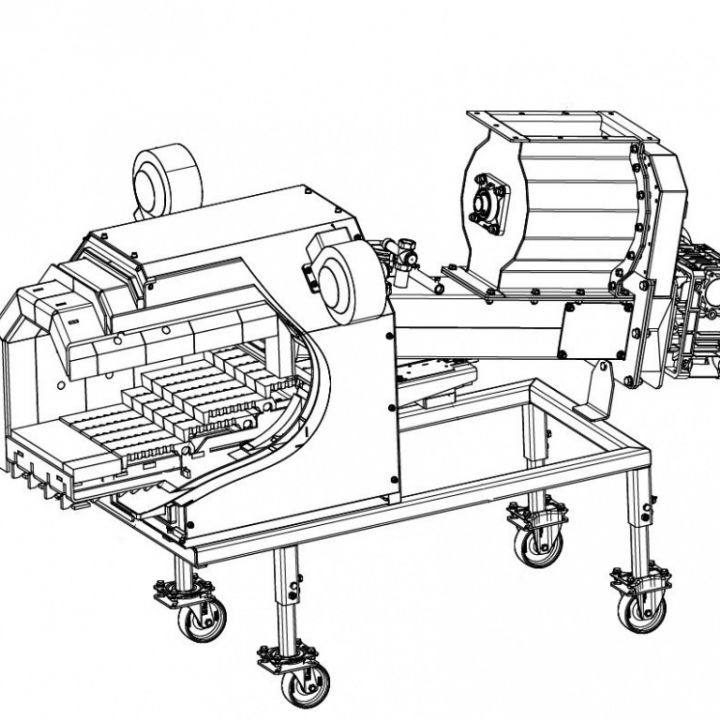

Spring Feeder

It allows to adapt existing room for fuel storage. Adjusting the angle of the feeder and rotation of the head relative to the feeder in the horizontal plane, allow the device to be adapted to the boiler rooms of various sizes and different layout of the rooms. These possibilities make biomass set a practical device.

Fuel containers

Available in sizes: 4m3, 6m3, 8m3, 10m3 and 27m3.

Equipped with stirring and fuelling mechanisms. Dedicated to the SMOK line, but also cooperating with other heating devices.

Control cabinets

These are modern devices designed to control the work of constructionally developed biomass sets equipped with screw feeders

Their functionality is individually selected according to the needs and technical conditions in which the devices are to be operated. Each of the control cabinets has the option of connecting the Internet Module, which also allows remote control of combustion processes and heat distribution

Control & Service Online

Advanced communication module. Access via Internet

It is an advanced communication module, facilitates remote control of operation of the boiler, via PC computer, smartphone and tablet with Internet access. The user is given the possibility to control all the parameters:

- temperature adjustments

- pumps and mixers operation

- monitoring of current regulator operation states

Clear visualization of the boiler operation history, presented in a form of charts is another crucial benefit for a user.

- remote control over the boiler parameters via the Internet www.econet24.com and mobile application for iOS and Android system

- intuitive software controlling the ecoNET module

- registry of parameters crucial for regulator operation

EcoSTER TOUCH

Remote control panel with room thermostat function

- Central management of heating installation

- Room thermostat

- Full scale of product customization

- Intuitive – clear and easy-to-use touchscreen panel.

- Unique design

- Individual temperature time schedules

- Alarms and fuel level information

- Software update with the usage of a microSD memory card

- Choice between different work modes